Steel & Metal Process

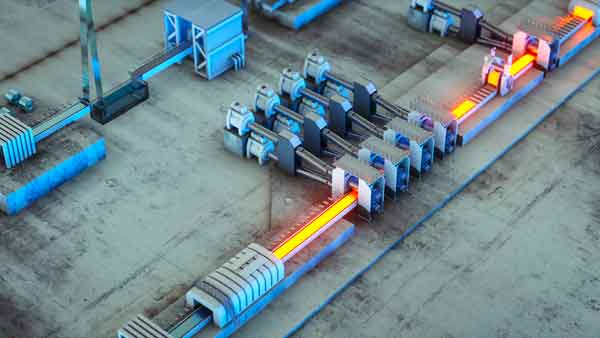

The Steel Manufacturing Process

The production of steel is a vital sector of the economy that affects the entire world. Since the middle of the 19th century, steel has grown to be one of the most widely used building and manufacturing materials in the world. The World Steel Association estimates that $2.9 trillion of the world’s economic activity is supported or made possible by global steel manufacturing, making it an essential component of millions of jobs worldwide.

Although steel production may not initially seem to be a commodity connected to cutting-edge technology, it has gone a long way. In this article on the production of steel, we’ll examine its past and contrast it with the production and utilisation of steel in contemporary applications.

Steel Production

The Iron Age, which began around 1200 BCE, is the era during which steel was discovered. The first iron ore was extracted in Central Asia and Europe, where iron was then employed in a process known as ferrous metallurgy to create tools and weapons. During this time, iron products developed, starting with wrought iron products made by blacksmiths. These craftsmen learnt to melt iron ore, and blacksmiths would purge impurities from the metal using a hammer and anvil procedure to create a strong and pliable final iron product.

Before iron finally took the form that is now known as steel, it underwent a number of additional transformations. Large furnaces were used in China’s Iron Age by metallurgists to heat iron, effectively melting it into liquid, and combining it with the wood fuel.

How Is Steel Made Today

Blacksmiths in Central Europe started using charcoal to cover wrought-iron goods after cast iron to increase the metal’s tensile strength while preserving its flexibility. After that, iron underwent one final transformation that is most similar to modern steel. Ironworkers in India created a method for smelting iron that mixed the ideal amount of iron with carbon. The ironworkers would combine chunks of iron and charcoal in a hot furnace using crucibles, or clay vessels. The iron would melt and take on carbon atoms from the charcoal during cooking. The crucibles eventually held an iron-carbon alloy that we now know as steel after they had cooled.

Following the discovery of iron-carbon alloys, numerous civilizations accelerated the manufacturing of steel, enabling them to create better structures, tools, and weapons.

In everything we do, all-encompassing and consistent quality management is at the forefront of our minds. Our broad product portfolio ranges from sophisticated sensor technology for demanding specialized steel making on to price-oriented solutions for standard steel plants.

Custom Metal Manufacturing

Steel is the ideal material to utilise in a variety of production capabilities since it is adaptable, inexpensive, and abundant. Steel is a valuable resource that original equipment manufacturers and other fabrication businesses rely on to create their unique parts and goods.

Businesses all over the world source steel and metal alloys to construct their products and realise their plans. A vital professional service in the global economy is custom metal fabrication and design since it enables companies to create new and useful products and take chances on avant-garde creations that assist mould and enhance our daily lives.

Welders, metalworkers, installers, and designers are just a few of the specialists involved in metal manufacture and design.

Applications

Automotive Manufacturing

In the manufacturing of automobiles, metal shaping is widely used. Most autos are made mostly of sheet metal that has undergone various metal forming processes. Sheet metals may only be formed into such complex components as automotive body panels, which frequently have various shapes and geometries, through the metal forming process.

Our expertise in the field

Steel is used in many various sectors, including transportation, building, and packaging. It is the material that contractors, engineers, architects, and fabricators favour due to its qualities including excellent durability, corrosion resistance, strength, and low cost.

Aerospace Engineering

Fuselages, wings, and engine parts are examples of applications in aircraft engineering. Although metal is more frequently utilised than composite material in the construction of fuselages and engine components because metal offers more strength than composite material, the majority of parts used in the construction of an aeroplane are built from either metal or composite materials.

Our expertise in the field

Steel is used in many various sectors, including transportation, building, and packaging. It is the material that contractors, engineers, architects, and fabricators favour due to its qualities including excellent durability, corrosion resistance, strength, and low cost.

Construction

Pipelines are one use for metal forming techniques in the building industry. Depending on the desired shape, hydraulic or electric resistance methods are used to create metal pipeline tubes. Recently, a novel technique known as air-forming has gained popularity since it makes it possible to produce seamless pipes.

Our expertise in the field

Steel is used in many various sectors, including transportation, building, and packaging. It is the material that contractors, engineers, architects, and fabricators favour due to its qualities including excellent durability, corrosion resistance, strength, and low cost.

Sensor solutions for the steel and metal industry

The steel and metal industry operates under some of the harshest environmental conditions — high temperatures, heavy dust, mechanical vibrations, and extreme humidity. These conditions demand robust, precision-grade sensor solutions to ensure safe, efficient, and uninterrupted operations across production lines, rolling mills, furnaces, and storage yards.

At Kelfos, we deliver industrial-grade temperature, humidity, and pressure sensing solutions specially designed to withstand the aggressive demands of metal processing environments.

The steel and metal industry presents one of the most demanding environments for sensor technologies, with high temperatures, intense vibrations, airborne dust, and electromagnetic interference being constant challenges. To ensure operational safety and process efficiency, accurate and reliable monitoring becomes essential at every stage — from raw material storage and furnace heating to rolling, cooling, and energy distribution.

Need a Consultation? Contact Us 24/7

Innovative Test & Measurement Solutions for Market Leadership