Packaging Industry

Sensors for the packaging industry

Everything is packaged, including food, medicine, and consumer items. With a comprehensive range of sensor systems, encoders, smart vision sensors, cameras, and process sensors, the Kelfos Group has long been a capable partner to more than 3000 equipment manufacturers in the packaging sector worldwide. Maximum process safety and flexibility with respect to the product to be packaged and the packaging itself are made possible by our sensors.

Additionally, Kelfos sensors facilitate the digital revolution of the packaging sector. To further optimize the operations, information other than the measured values can be processed using standardized digital communication interfaces, including IO-Link or fieldbus-based interfaces.

Reliable sensor solutions for demanding filling and cleaning processes

The Kelfos Group positively affects food safety by meeting the particular requirements in the production and packaging process. Additionally, the packaging process must meet the expectations for improved machine performance and adaptability. Our solutions are preferred by machine manufacturers that want to reduce complexity. The configuration of individual machine modules guarantees that the component systems connect to form an ideal whole system in terms of industrial and customer needs.

KELFOS offers sensor solutions engineered to meet the rigorous demands of modern filling and CIP/SIP cleaning processes. Whether in food and beverage, pharmaceutical, or chemical applications, our sensors deliver accurate measurement, robust performance, and compliance with hygiene standards.

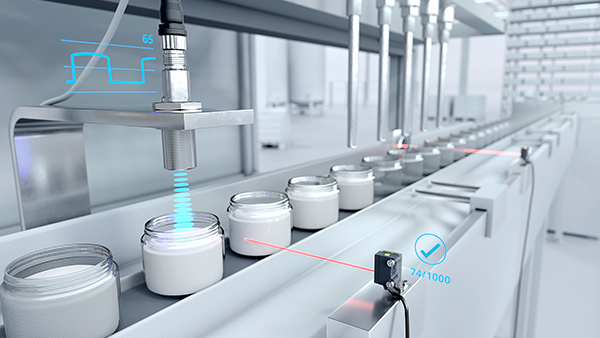

Smart Sensors for Production & Packaging

The Kelfos Group positively affects food safety by meeting the particular requirements in the production and packaging process. Additionally, the packaging process must meet the demands for improved machine performance and flexibility. Our solutions are preferred by machine manufacturers who want to reduce complexity. The configuration of individual machine modules guarantees that the component systems connect to form an ideal whole system in terms of industrial and customer requirements.

Real-time quality inspection systems are essential for ensuring that every label applied during high-speed packaging processes is present, correctly positioned, and meets stringent quality standards.

Benefits for Demanding Processes

Maximum Food and Process Safety: All sensors are designed to meet strict hygiene requirements and are certified for use in food, beverage, and pharmaceutical industries.

Operational Efficiency: Fast response times and high accuracy enable optimized material usage and reduced downtime.

Flexibility: Suitable for a wide range of media and process conditions, including those with frequent product changes or challenging media properties.

Reduced Maintenance: Durable, robust designs minimize maintenance needs and extend sensor life, even under harsh cleaning conditions

Applications

Object Detection and Positioning

Photoelectric, inductive, and ultrasonic sensors are used to detect the presence, position, and orientation of packaging materials and products on conveyor belts. This ensures accurate product handling, alignment, and sorting during packaging and labeling operations.

Our expertise in the field

With extensive experience in industrial automation, we deliver advanced object detection and positioning solutions tailored to the dynamic needs of the packaging industry. Our expertise is built on a deep understanding of the challenges faced by manufacturers—such as handling varied packaging materials, ensuring process reliability.

Level and Volume Measurement

CleverLevel and other level sensors monitor liquid levels in filling machines and storage tanks, preventing overflows and ensuring precise dosing. Laser sensors like the OADR 20 series provide high-accuracy volume measurement for products such as meat and cheese

Our expertise in the field

Our team brings deep expertise in level and volume measurement for the packaging industry, ensuring precise, reliable, and hygienic solutions tailored to your process needs. we deliver level and volume measurement solutions that drive efficiency, safety, and quality throughout your packaging processes.

Quality Control and Inspection

Kelfos smart cameras and code readers verify package integrity, read barcodes or QR codes, and ensure correct labeling. These solutions help prevent defective products from reaching the market and support traceability

Our expertise in the field

We specialize in delivering advanced quality control and inspection solutions that ensure consistent product integrity and compliance throughout packaging production. Leveraging Baumer’s state-of-the-art sensor and camera technologies, our expertise enables manufacturers to achieve 100% quality assurance with minimal downtime and maximum efficiency.

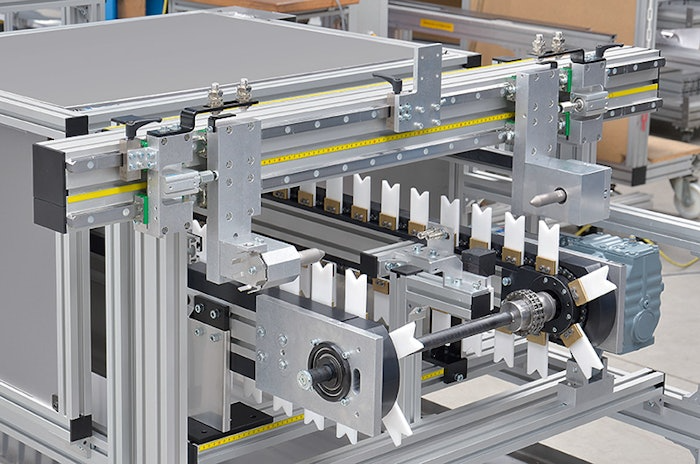

Labeling machines for self-adhesive labels

Self-adhesive labeling machines are essential for industries demanding fast, precise, and flexible label application on a wide variety of containers and packaging formats. To achieve consistently accurate labeling—especially in high-speed, dynamic environments—advanced sensor solutions play a critical role.

High-Speed, High-Precision Detection

Modern labeling machines utilize advanced photoelectric and ultrasonic sensors to detect container presence, position, and orientation with millisecond response times.

Label Position and Registration Control

Ultrasonic sensors and specialized label sensors accurately detect the leading edge of transparent, opaque, or multi-layered labels.

Need a Consultation? Contact Us 24/7

Innovative Test & Measurement Solutions for Market Leadership