Refrigeration

What is the Refrigeration Industry

Industrial refrigeration includes a wide range of operations, from low-temperature freezers to high-temperature process chilling. Industrial refrigeration is a significant industry with a significant economic impact on sectors like food processing and construction.By lowering the temperature to a set point, industrial refrigeration aids in eliminating heat from large-scale processes or materials. Industrial refrigeration can be applied using a variety of techniques depending on factors including temperature differential, temperature accuracy, and volume of output.

Refrigeration systems: essential for industries!

For many sectors, from District Cooling to Data Centres, to function properly, refrigeration and cooling systems are essential. For residential or commercial real estate projects, hotels, hospitals, universities, and businesses, industrial refrigeration, particularly District Cooling, can have significant economic and environmental advantages. The many cooling systems and sizes that are currently available reflect the unique requirements and factors that apply to each sector. In line with this, no matter what industry you work in, specialised industrial refrigeration systems and solutions that are simple to adopt, like those provided by ARANER, are a powerful instrument to increase efficiency and boost productivity.

Representation of a simple absorption refrigeration cycle

Generator: In the generator, a heat source converts a strong ammonia solution into ammonia vapour. The rectifier is used to dehydrate the ammonia (refrigerant) vapour before it enters the condenser.

Condenser: Ammonia that has been dehydrated and heated enters the condenser where it is condensed. After cooling, it passes through an expansion valve (throttle valve), which lowers the pressure and temperature. The modified values must be lower than those that the evaporator (the following stage) maintains.

Evaporator: At this point, the evaporator, which is effectively a cold refrigerator, appears. The evaporator receives the cooled ammonia, which subsequently absorbs heat and exits as saturated ammonia vapour.

A mild ammonia : water solution is sprayed onto the vapour as it enters the absorber. The weak solution eventually transforms into a strong one. The regenerator (also known as a heat exchanger) is where the new solution is sent by the pump on its way to the generator. The pressure has already reached generator/condensing level by the time the solution arrives. The procedure begins once more.

Industrial refrigeration applications are frequently utilised in establishments like cold storage facilities for food, dairy processing facilities, beverage production facilities, ice rinks, and heavy industries. These cooling systems are on a grand scale.

Where do we find industrial refrigeration systems

Industrial refrigeration applications are frequently utilised in establishments like cold storage facilities for food, dairy processing facilities, beverage production facilities, ice rinks, and heavy industries. These cooling systems are on a grand scale.

Other varieties of commercial building cooling systems, supermarket CO2 systems, chillers, and schematics for chilled water have all been previously discussed. If you haven’t already, be sure to check those out.

Applications

District Cooling

One of the biggest cooling markets focuses on supplying cooled air to urban and touristic locations to maintain comfortable enclosed environments regardless of the weather outside. District Cooling systems are typically used to offer refrigeration production in large hotels, resorts, and district regions.

Our expertise in the field

The idea behind district cooling is to create cooling streams in a central facility using various technologies, primarily chilled water. Then it is disseminated to various inhabited locations, such residences, workplaces, gathering spaces, or other residential or commercial developments.

Electricity Production

The combustion of various fuels is frequently the basis for the production of electricity. Inlet air needs to be in specific conditions in order to achieve a greater efficiency. Too much heat in the incoming air causes its density to drop, which lowers the amount of electricity produced.

Our expertise in the field

When running, other components of the production and distribution networks, such as distribution centres or electric generators, also produce heat. Refrigeration systems are required to reduce maintenance tasks. Typically, compression or absorption cycles are the foundation of this refrigeration device.

Chemical & Petrochemical

Although the reactions in the chemical and petrochemical industries are not as carefully regulated as those in the pharmaceutical industry, temperature control is a crucial element in achieving high efficiency in these transformations. Large-scale cooling facilities are utilized in the chemical and petrochemical industries.

Our expertise in the field

After the heat has been dissipated in the various procedures, the hot stream is cooled using compression cycles and absorption cycles. Additionally, heat exchangers are typically used to heat these streams and increase the operation’s efficiency because hot streams are needed in other stages of the process as well.

Pharmaceutical

The pharmaceutical industry is built around operations where precise requirements must be met for each phase to be successful. Further, many industrial processes involve biological or biochemical processes that can only occur under very specific circumstances that allow microbiological species to produce chemical compounds at their highest output.

Our expertise in the field

Temperature is one of the most crucial factors in this field. Additionally, strains used to produce drugs and medicines are kept in extremely controlled environments, typically at very low temperatures. These factors force the pharmaceutical business to rely on very advanced refrigeration systems that allow rooms and storage units.

Refrigeration technology

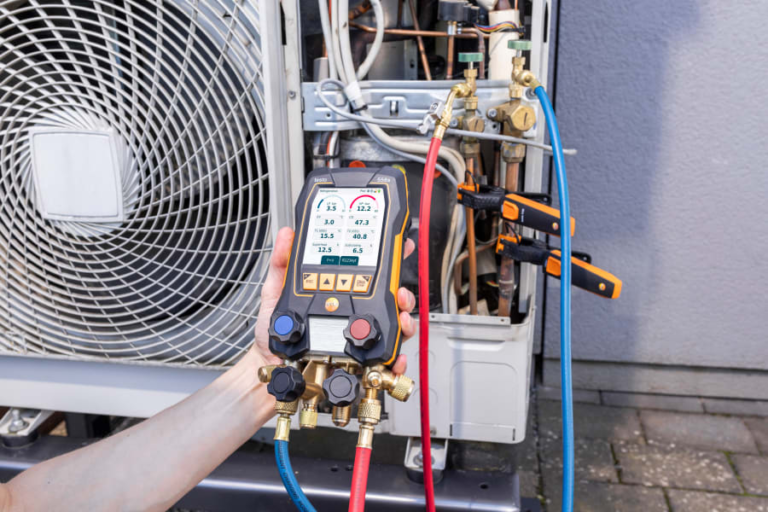

Pressure, temperature, superheating and subcooling of a refrigeration gadget have to be checked to make certain it features smoothly.

Kelfos digital manifolds provide most precision in this region and are a long way gold standard to analog manifolds. They additionally file tightness at lightning speed, observe even the smallest leaks and reliably evacuate refrigeration systems.

Find out about service, calibration and education as well. For best cooling overall performance with most reliability and efficiency.

Need a Consultation? Contact Us 24/7

Innovative Test & Measurement Solutions for Market Leadership